.png)

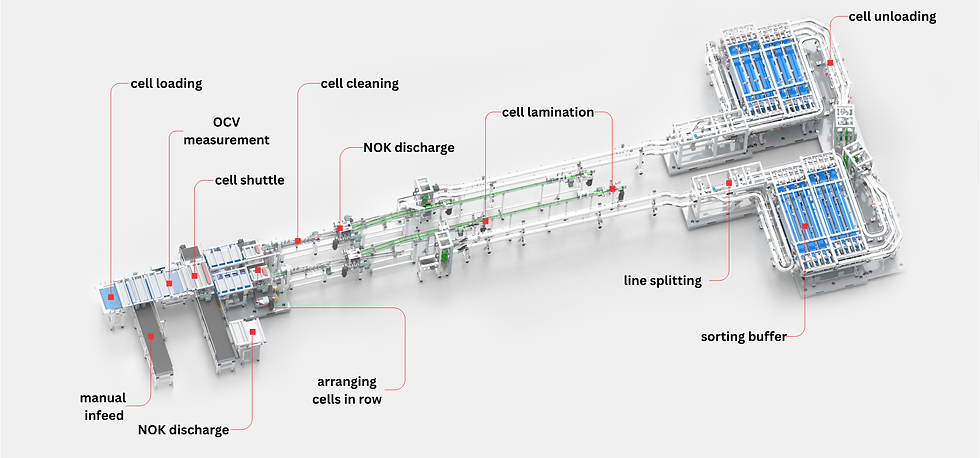

Prismatic cell feed

From cell placement and comprehensive testing procedures to precise stacking – with deep process expertise, scalable automation solutions, and the highest quality standards, we are your reliable partner for demanding battery manufacturing projects.

Cell feed round cells

Cylindrical cells place high demands on cycle times, product handling, and process reliability. In multiple customer projects, we have successfully met these challenges with customized automation solutions and proven expertise.

.png)

semi-automated battery production line

The battery sector is as diverse as it is demanding – ranging from large-scale energy storage systems to compact batteries for small devices. We offer tailored turnkey solutions for semi-automated production lines – efficient, flexible, and cost-effective.

manual battery production line

Automation is not always economically viable – especially with low production volumes or frequently changing product variants. We provide expert support in setting up a manual production line tailored precisely to your processes and requirements.