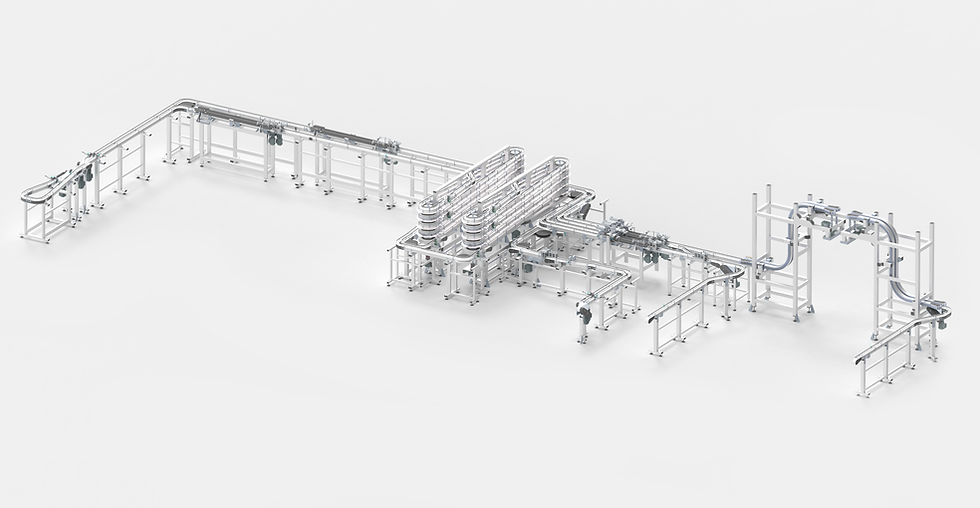

Conveyor systems

Our modular conveyor systems enable the implementation of virtually all requirements in the transport and handling of unit loads. They are applicable across industries and can be flexibly adapted to customer-specific processes. Combined with our buffer and storage systems, as well as individually developed special systems, they ensure a consistent and application-oriented material flow solution.

Flex System

The Flex System chain conveyor system enables the implementation of complex routes in three-dimensional space with just one continuous conveyor – without any separation points or transfer points.

Realization of sophisticated 3D route layouts

Robust construction

High operational reliability due to minimized risk of crushing and quiet operation

Process unit

Process units specifically supplement the internal material flow where process-technical requirements cannot be met using conveyor systems alone.

Possible applications are:

Turn/Twist

Positioning

Distribute/Merge

Workpiece carrier system

Our conveyor systems are designed for use with both our own and customer-supplied workpiece carriers (WT). The systems are individually tailored to the specific requirements regarding the weight and dimensions of the workpiece carriers.

Customer-specific system design

Compatibility with factory and external WT systems

Modular conveyor

Modular belt conveyors enable the three-dimensional transport of unit loads over inclines, declines, and curves. They offer high flexibility in terms of chain type and width and can be optimally adapted to individual requirements.

Selection of different chain types and widths

Tailor-made design for specific applications

Conveyor solution for straight and curved routes

Assembly and testing technology

Our assembly and testing systems are based on our conveyor systems, which are specifically enhanced with customer- and process-specific assembly and testing steps. The focus is on processing small, piece goods at short cycle times – ideal for demanding, highly dynamic production environments.

Transfer systems

Transfer systems connect individual production and assembly stations into a continuous manufacturing process. In addition to simple workpiece feeding, they also perform functions such as the ejection of non-conforming parts (NOK) and the integration of inspection and detection units for quality assurance.